German initiative “Industry 4.0” stands for intelligent networking of production and logistics, that is two domains, but also aspires to optimize ERP and PLM systems respectiveley. What fundamental changes will there be when Industry 4.0 scenarios, that is industrial production based on clear individualization of products in the conditions of extremely flexible mass production, become established? Our editor broached this subject with Kerstin Geiger, Global Head of Industry Business Solutions – Discrete Manufacturing Industries with SAP.

German initiative “Industry 4.0” stands for intelligent networking of production and logistics, that is two domains, but also aspires to optimize ERP and PLM systems respectiveley. What fundamental changes will there be when Industry 4.0 scenarios, that is industrial production based on clear individualization of products in the conditions of extremely flexible mass production, become established? Our editor broached this subject with Kerstin Geiger, Global Head of Industry Business Solutions – Discrete Manufacturing Industries with SAP.

An interview with Bernhard D. Valnion

Dr Geiger, how can processes of self-optimization, self-configuration, self-diagnosis and cognition, topics we read about in the literature on Industry 4.0, be supported by ERP?

To get straight to the point, in the view of SAP, Industry 4.0 is not just about production and logistics, but also novel products and their efficient delivery and service. And namely for the following reasons: for some time now we have observed a considerable shift in the value chains of our customers. These continue to develop on a grand scale from product to service providers.

Yes, there’s a lot of talk about that. SAP, however, seems to be actually observing this trend. Could you give us a concrete example?

A very good example is Hilti, which no longer sells drills, but “holes” – the drill itself remains in the possession of the company. We could tell you something similar about Käser compressed air systems. This company sells to its customers what they really need: compressed air. It is therefore important to factor the entire lifecycle of a customer relationship into the calculations. Just take the new integrated mobility concepts or the building trade as examples.And along with this the work of the engineer will change radically. I myself studied mechanical engineering and learned to develop products in compliance with specifications and with certain functions, to meet quality requirements and cost structures…

…it seems to me that new light will now be shed on the somewhat hackneyed slogan of “lifelong learning”.

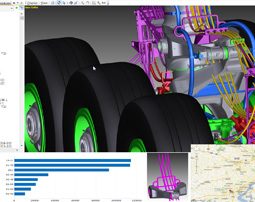

We are observing a definite trend away from conventional classroom learning to context-sensitive provision of information when there is a real need for it. Let’s take tractors as an example: these multipurpose vehicles are now absolutely high-tech machines. If a problem occurs when the tractor is working in a field, it is essential to provide the tractor driver with the data relevant for the situation, visualization of the content being a key component, for instance to ensure any necessary repair is made as quickly as possible. It doesn’t make much sense to train the driver for weeks beforehand to prepare them for every possible eventuality and intervention. You understand why we put so much emphasize on our visualization strategy based on the SAP Visual Enterprise portfolio.

Yes, indeed. How does SAP stand with regard to these upcoming challenges in total?

In several ways, of course. Just think about the acquisition of Sybase, which brought comprehensive technology for the support of mobility applications under our roof – we can communicate with smart devices. Moreover I should like to point out the remarkable innovations in our database technology HANA. We can’t just connect portable devices, but also import and analyze data from them. And we are working intensively on issues concerning predictive analysis.

SAP took part in the “Industry 4.0” working group and contributed to the final report, which was presented to the German Chancellor Angela Merkel at the last Hannover Messe. What are the reasons for your involvement?

In the first step, it was important for us to analyze the entire scope of Industry 4.0 and where we stand today with our portfolio. For this reason we worked together with Acatech on this. We identified spheres of activity where we want to complement our portfolio. By the way, we have announced a HANA-based application for predictive maintenance. And, at last Sapphire we have released the HANA-based application for Material Resource Planning (MRP) in the factory. This makes inventorying stocks much more transparent, e.g. which orders are made over the next few days and what material is required. This information in turn is crucial for better planning and acquisition of inventory and its minimization.

With regard to the connection of feedback loops with experience from production and operations – what approaches is SAP taking here?

This is going in the direction of predictive analytics again. We already provide instruments that help close loops. You have to remember that even with a new product development, an average of 80 percent customized design still has to be done. For the development, it is therefore extremely useful if the users can work with reference to the context. For example: how is the component used in what constellation? Or: Is something similar already in operation in the field? Is this any feedback on this? Any warranty claims even? Nowadays for the acquisition of such information, a huge amount of manual work is necessary. If now, however, it is possible to connect machines and components and to collect their data, such valuable conclusions can be drawn in a much shorter time. Here therefore big data applications will be very exciting. Large volumes of data can be analyzed much more flexibly than with conventional data warehouse applications, in which basically you have to know beforehand which analyses are of specific interest.

With which additional interfaces will we be confronted?

That is a separate field of work. I find it remarkable that German associations VDMA, Bitkom and ZVEII are taking the same road here – although I do hope that things will speed up a bit. You should know that the definition of interfaces can very easily drag on. On the other hand, the flexibility of the entire value creation network stands or falls with it.

Many thanks for your comments!

Interview: Bernhard D. Valnion