Hier lesen Sie einen Beitrag mit dem Produktmanager von CAD Schroer, Mark Simpson, über das, was das 2D-/3D-CAD-System Medusa4 so einzigartig macht. Das Interview wurde in englischer Sprache geführt und ist in ECONOMIC ENGINEERING 1/2016 erschienen.

Mr Simpson, what were the main drivers for latest release 6 of Medusa4?

There were three main objectives: User Experience, Platform Evolution and, of course, the technical improvements which everyone expects. For software with a long lifecycle, it is vital to review your product totally on a regular basis and on occasion revisit everything and refresh it for the next few years. A fine balance between modernizing and disrupting very productive customers.

What do engineers expect with regard to usability?

CAD products have to be useable ‘straight from the box’ with little or no training. They want a downloadable trial before making any contact with us. Like all good software vendors we add to our toolset in response to customer requests over time; the only downside to this is that the number of tools grows steadily. We’ve taken this opportunity to combine, merge and improve our toolset; in the case of MPDS4 from around 370 tools to less than 100 without losing any functionality and improving significantly the ease of getting started…

…that is an amazing reduction!

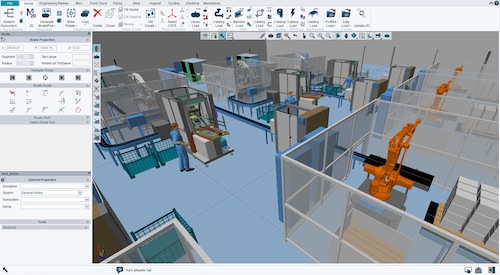

Hardware platforms continue to evolve, perhaps driven more by the mass market today than the engineering and scientific community. We love the graphics power that’s games have added to even cheap computers; our MPDS4 plant products love this! The rapid migration of displays from fairly square to wide screen offers more challenges; so we’ve added a ribbon to the top of our user interface and moved all of the feedback and catalog tools to the vertical edges in dashboards. We’ve even found a practical use for touch screens; displaying catalogs on a touch screen tablet is an exciting new possibility.

Can you highlight some of the new features or functions?

Sure. We’ve added nearly 70 separate technical feature projects on top of the user experience work already detailed; many are obviously integration and combinations of existing tools.

We’ve merging the mechanisms for selection, insertion, translation and positioning catalogue components and equipment so that one set of skills and visual cues delivers 60 percent of all user interaction. Clearly much simpler to learn and obviously easier to remember, especially if you are a part-time user.

What is CAD Schroer’s answer to most recent trends such as Building Information Modeling?

Whilst BIM is of future interest to get hold of building envelopes we’ve added export of whole project databases to ISO15 926, the BIM. of the plant design world if you like. You can export geometry, structure and attributes and, in some cases, make native formats to import directly into other systems. A big step for our Tier1 and Tier2 customers who send content to EPCs

Another strength of MPDS4 is its mechanical handling functionality. Can you provide as some examples?

Sure. An intelligent set of parametric catalogue components to represent many types of conveyors, overhead assembly lines, cranes, forklifts et cetera. We’ve extended the range greatly in this release with more flexible content; designed to easily take on the characteristics of most manufacturer’s equipment.

Can you handle point clouds?

Yes. We’ve also added the ability to display and hit point clouds within the design environment, a great way to mix the old and new in one space. Our simple graphics clipping plane becomes multiple clipping boxes, the need to clip point clouds separately to other graphics is a must. We’ve paid lots more attention on how to create, update, dimension and keep drawings consistent; we have one of the fullest 2D systems on the market but you can always optimize the production of drawings. Our M4ISO unscaled pipe isometrics system is fully automated, making pipe Isos direct from 3D in seconds.

One area where 3D adds huge benefit outside of detailed design is in selling and customer review. Our MPDS4Review product has also received the same user experience improvements; allowing our customers to share their designs with their customers using small easily transportable data sets.

Medusa4 addresses different markets such as machinery or large-scale manufacturing industries. With regard to the technology: How can you manage these different requirements?

We have one base kernel of software for geometry and user interface, onto this are built two main application product families:

• Medusa4 for drafting, diagrams, basic 3D, raster and so on

• MPDS4 for very large scale assemblies with intelligent applications for piping, steel, electrics, ducting, and mechanical handling.

The kernel provides a wide range of interfaces for geometry, access to databases and data sources and a significant number of integrations with PDM, MRP and ‘lifecycle management’ products.

Process plant and factory design benefit greatly from 3D design methods, but many of the inputs and outputs are 2D and BOM. Having our own integrated product set for both makes for great integration between the two environments.

Many of our customers have migrated with us to detailed 3D design whilst still starting from large scale 2D layouts; often all their customers have to offer. We’ve a unique mechanism for building 3D background from such layouts as well as adding 2D symbols of their products to build the 3D design — fast, efficient and you have to produce the drawings anyway.

CAD Schroer also delivers development services. Why is that?

It’s a key differentiator for us that you can engage with the software vendor to add productivity features to the out-of-the-box system. Many customers use the software just as they downloaded it from us; but a proportion come to us for extra features and integrations. Looking backwards in time many customers had large departments managing their CAD systems, now many don’t have a full time administrator, so you find that things are sometimes less smart than twenty years ago.

Can you give us an example?

For example it might be simple to type a BOM from a drawing into your materials management system once, multiply that by hundreds of engineers and thousands of assemblies and you waste a lot of resource! We automate these things and then support them over the years directly for the customers.

Another example would be automated drawing production from the output of a customer’s own calculation or configuration system; from tyres to trucks, detailed drawings to general arrangements we do them all.

We undertake projects from a few days to hundreds of days; our customers buy them from us because we are very good at it, price sensibly and will be there for years to come to upgrade and improve things – a vendor with which you form a real relationship.

Medusa4 survived as a CAD product over many decades? What is the secret behind that remarkable success?

One key item is surely quality dimensioned drawings, perhaps not as fashionable as 3D printing, but they are still the lingua franca of the engineering world. It’s true that they are rarely printed these days but they still form the basis of most engineering contracts. How it’s dimensioned tells you how to measure it and often how to make it; something more subtle than simply displaying the parameters of a solid model. Drawings are of course also the easiest format to share with customers, partners and contractors.

Intelligent integration with lifecycle management tools is key for many companies. What does CAD Schroer provide?

Your are right. It is not about simply storing files, but extracting and updating drawings and 3D models as part of the Store/Retrieve/Approve process. We insert BOMs into SAP, add revision history to drawings automatically and produce the distribution formats in the background. Today, many engineers spend more time feeding their data management than creating designs; we can really improve that.

We work well with the other 3D CAD systems. We use our own technology to extract enough from their complex assemblies to allow us to assemble their machinery designs into our much larger scale plant world. Whilst one department might work very productively with Creo, Inventor or Solidworks to design standard machines; other departments place specific machines into their customer’s world, needing buildings, services and 3D visualization to sell and install them. We commonly build assemblies with thousands or hundreds of thousands of machines and catalog parts, producing drawings and BOM as outputs.

Thank you for your comments!

Interview: Bernhard D. Valnion