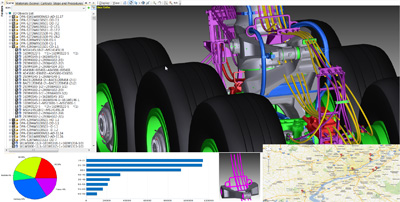

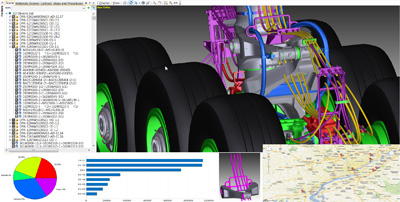

Northrop Grumman Corporation (NGC) is a premier developer, integrator, producer and supporter of manned and unmanned aircraft, spacecraft, high-energy laser systems, micro-electronics and other systems critical to maintaining the nation’s security and leadership in science and technology. Its business sectors are split up into aerospace systems, electronic systems, information systems, and technical services.Centers for product development and of course the supplier base are scattered around the globe, meaning all aspects of global collaboration are a big issue for the OEM. The suppliers alone are located in 18 different countries – so translation really matters.In discussion with our editors, Shaugnessy (“Shag”) Reynolds, Director Lifecycle Logistics & Support Aerospace Systems Sector & Unmanned Systems with NGC, remembers the beginning of a unified visualization strategy based on the Right Hemisphere/SAP technology. “Some eight years ago, in the Joint Strike Fighter (F 35) project we wanted to deliver better training manuals. We had some initial ideas to realize this with the help of Right Hemisphere technologies.” A single implementation program was started and meanwhile the SAP visualization technology has been rolled out in more than 17 different product programs. “For us, one of the key things was efficient knowledge transfer from the older experts to the younger colleagues, and to new employees. We were going from a 2D type of documentation to 3D. That has been one of the strategic initiatives over the last five years to continue on our visualization path,” Mr Reynolds explains.Owing to the demographic change, a lot of experts are in the 50+ age group. Moreover, in the last few years staff fluctuation has been high – it was the time when .com companies took everybody out in order to grow. Sure, this was not only a difficulty for NGC but an aerospace-industrywide problem. NGC therefore needed a different approach to knowledge transfer.To realize that, NGC has installed and is utilizing several licences of SAP Visual Enterprise Generator as a centralized single instance. Different Teamcenter derivates (Engineering/Enterprise/Unified) of Siemens PLM Software are acting as the PLM backbone. And SAP Visual Enterprise Generator is connected to these multiple instances of Teamcenter.Hundreds of SAP Visual Enterprise Author licenses are being used to create training documentation in logistics and now manufacturing work instructions too. They are available across all aerospace sector programs. The SAP Visual Enterprise Viewer is used to visualize the content authored for the training and for shop floor work instructions in the assembly process.

Multi-CAD environment

Although Catia V5 is the CAD backbone, the company is running a multipole CAD environment because Catia V4 and Pro/Engineer are also in use. A lot of other CAD systems must be added to cater for collaboration with an extended supplier base. “That is one of the great benefits,” Mr Reynolds emphasizes, “to pull the full original engineering data and being able to repurpose it with the use of the Deep Server technology. In other words: to have the ability to take those large files and render them down. Frankly, the visualization within Catia is not as good as that of Right Hemisphere. Catia requires a long pipeline and the bandwidth needed is huge when we want to send the files all over the world.” But what does Mr Reynolds really mean by “knowledge transfer”? “As we develop our products and as we try to communicate our initial designs to other engineering departments or to the supplier base, which is geographically separated, it is a lot easier and a lot more efficient using powerful visualization techniques,” Mr Reynolds explains. So, one side of it is the effective communication within the engineering and design community. Another benefit: “Product and process renderings enable us to present the customers our solution concepts in early phases, i.e. there is a market development aspect that allows us to be more efficient.” NGC is engaged with a lot of US Department of Defense and other Ministry of Defense customers. They want to know in detail how to operate the products. “For us it is important to be able to communicate to them across the different US military services but more importantly in the international market space where a picture doesn’t need to be translated – everybody understands that,” the manager says, getting to the main point. When you look at visualization in NGC’s production, you recognize additional pros: manufacturing engineering has to talk to the assemblers and the factory workers. And “with 3D work instructions, they are able to better understand and be more precise in producing our products,” Mr Reynolds says, not forgetting to mention: “Finally, when you look at this in the support and the operations realm, you realize: you can train to utilize this product with the help of 3D models much better and you are able to share that knowledge, for example with the technical data packages for the maintainers to repair in the product line out in the field.” This is much more efficient than going through a bill of material or an integrated part break-down and figuring out: where is that #.123 part?

Wrap-up

SAP Visual Enterprise reduces rework with in NGC eco system because it helps to avoid confusion in the design process and it also reduces confusion in the product line in the build phase. In addition, “it allows us a faster repair infrastructure. And that’s a big issue if you look at cost per flight hour: the repair part is historically 26 cents of every US dollar. So we are able to support our products much more efficiently. Keep in mind, today even the defense sector is much more economic-driven than it was two decades ago,” says Mr Reynolds, referring to the business benefits. Nowadays, all the stakeholders have to agree in a faster cycle, meaning that knowledge must be shared at a quicker rate: “That is one of the reasons why we believe in 3D and in the SAP technology to meet that challenge.”

BERNHARD D. VALNION